As one of the fastest growing conventional printing processes in packaging, films and corrugated containers, flexographic printing is versatile, reliable and produces premium quality results.

Initially rudimentary in printing quality, the printing style’s evolution since the 1990s in printing presses, plates and inks has made room for superior results and is now used extensively in process colour printing on a wide selection of materials and is found more commonly in narrow web printing.

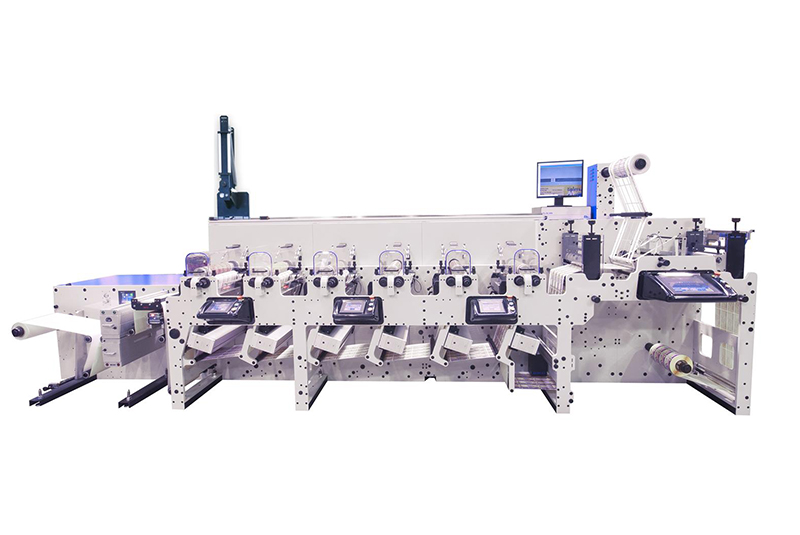

Much like a letterpress, our flexographic printing machines use flexible printing plates made of rubber or plastic. These are inked with an image which is rotated onto a cylinder and then transferred onto the chosen material. You will find that our range of machines all use fast-drying inks and work at high speeds which can all be modified. This means you can cater your chosen piece of Focus Label printing equipment to suit your desired output and requirements.

At Focus Label we design and manufacture a wide selection of paper and packaging equipment suitable for various flexographic printing results which you will find below. Whether you require more bespoke printing options for larger dimensions of material or high volumes of production, we can advise you on the right option to suit you.

Various machines are available for numerous flexographic applications, however should you have more specialist requirements or be unable to find a particular printer that suits your needs then we can direct you further.

With our extensive experience and knowledge of the printing industry we can also assist you in terms of the right training and support to suit your purposes or workforce.

Reflex Machine & Digital Finishing Equipment

Proflex SE Machine

eFlex Machine

Inspection Rewind System Machine

Ultrasonic Anilox Roll Cleaning Machine

Platemaking Systems Machine

Centraflex Machine